There are several metals which are used for manufacturing pipe fittings which brass fittings manufacturers manufacture. However it’s a known fact most alloys prove to be stronger as compared to metals. One such example of an alloy which is very popular for it strength and ductility is indeed brass.

Due to its composition that is zinc and copper, it is widely used in manufacturing pipes which are used in HVAC products. They are very highly in demand due to its properties which consists of fire resistant, chemical resist, high in ductility, flexible and most importantly strength. Since they are very flexible and ductile therefore they can be formed into various shapes and sizes and are mainly used to connect two different things.

Not only they have all the above characteristics but also they are very easy to finish them. When it comes to plating, polishing and joining them they are one of the best alloys to work on. The after effect and the final presentation is very superior and provide a great result.

There are two kind of brass namely yellow brass which consist more of zinc than copper and red zinc which consist of copper more than zinc. Both kind of brass has it’s their own advantages and disadvantages. In case of red brass, they are known for its strength and in case of yellow brass it is known for its elasticity and flexibility.

When we talk about red brass the best thing about the same is that it is water and heat resistant and when in best suitable for pipes ,as it does not react with the salts present in the water, thus does not lead to corrosion. Other than that it also works out to be the most appropriate platform for easy flow of liquid hence is most preferred material for manufacturing of pipes.

What Are The Various Kind Of Pipes Made Out Of Brass?

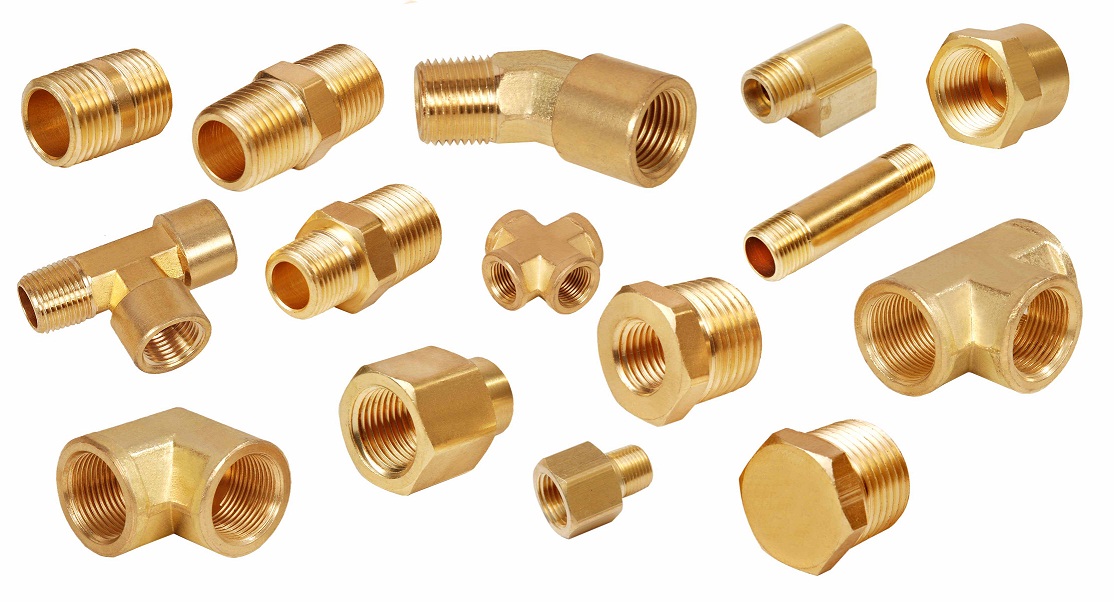

As mentioned above brass is very easy to be carved and made into various shapes and sizes thus a variety of sizes and configuration can be manufactured with the help of molten brass.

- Brass Compression Fittings –They provide the advantage of easy assembly, with no flaring and can be manufactured in various sizes and dimensions. They can be used along with copper and aluminium as well with plastic covering.

- Brass Flare Fittings – Brass Flare fitting is mostly used in manufacturing of Hydraulic brake, Industrial, Plumbing and can be used again and again as it does not undergo any major wear and tear. The threads remain protected without any damage and are easy to use.

- Brass Barb Fittings – Brass Barb fitting has loads of advantages as compared to its counterpart, they are temperature resistant, acts as a wonderful lubricant and support vacuum and fluidic systems. Since they have an excellent resistance therefore are most suitable for manufacturing pipes through which hot liquid can flow.

These are just a few examples of brass equipment which brass pipe fittings manufacturers manufacture. With a growing demand for brass supplies, brass fittings manufacturers are going an extra mile to provide more versatile products.