Gearless elevator machines are linear vertical lifts for home and commercial use. Not only is the Gearless Drive System an environmentally friendly solution, as it uses no fossil hydraulic oils. It also has reduced energy consumption due to the use of a counterweight mechanism.

This counterweight mechanism balances the car’s weight and half of the load that the car can carry. Therefore, it uses upto 90% less energy than any other system.

The gearless elevator machines consist of 3 main components –

- The gearless motor

- The motor brakes

- The Overspeed Governor

- The gearless motor

Unlike other lifts that use a cheaper old-school gearbox motor, the gearless uses a much more advanced gearless motor. This means there is no wear and tear on gears due to friction. It doubles the lifespan and splashes the energy consumption in half. In any new lift, safety has the highest priority.

- The Motor-Brake

When the lift is in regular operation and arrives at the desired floor, the motor is held in position by a double motor brake. This makes it impossible for the lift car to move. If the main power fails, the battery backup system will use this brake to slowly bring the car back to the nearest floor and open the doors.

- Overspeed Governor

If this speed exceeds the average speed of the lift, the device will pull the brake shoe on the lift car and bring it to an immediate standstill.

As we already know, there are two types of elevators – – geared and gearless. The gearless elevator machines are gaining more attention among people than geared elevators. The gearless elevator also has more advantages than a geared elevator. It provides extra features with easy operation.

Types of Gearless Elevator Machines

- Traction elevators

This works by passing the ropes over the wheel. The wheel is connected to an electric motor, finding the elevator shaft above the motor. These elevators traverse more rapidly than hydraulic elevators. Thus, it will not require much weight to move from one place to another in this elevator.

- Geared Traction Elevators

In this type, you can find a gearbox that is fixed to the motor. The motor will help the rope to move where the rope is attached to the wheel. It drifts so fast, like 500 ft per minute.

- Gearless Traction Elevator

In this type of elevator, you can find the wheel next to the motor that is being attached. This Gearless traction elevator can travel faster than geared traction elevator for 2000 ft per minute. Thus, the gearless traction elevator is the best among all other elevators because of its fastness and reliability.

Components of Gearless Elevator Machines

- Headroom:A portion of the shaft between the top floor and the shaft’s ceiling. Headroom is otherwise known as Overhead.

- Travel: The length of the cabin’s travel between the level of the lowest and the highest stop.

- Pit:A part of the shaft below the level of the lowest stop.

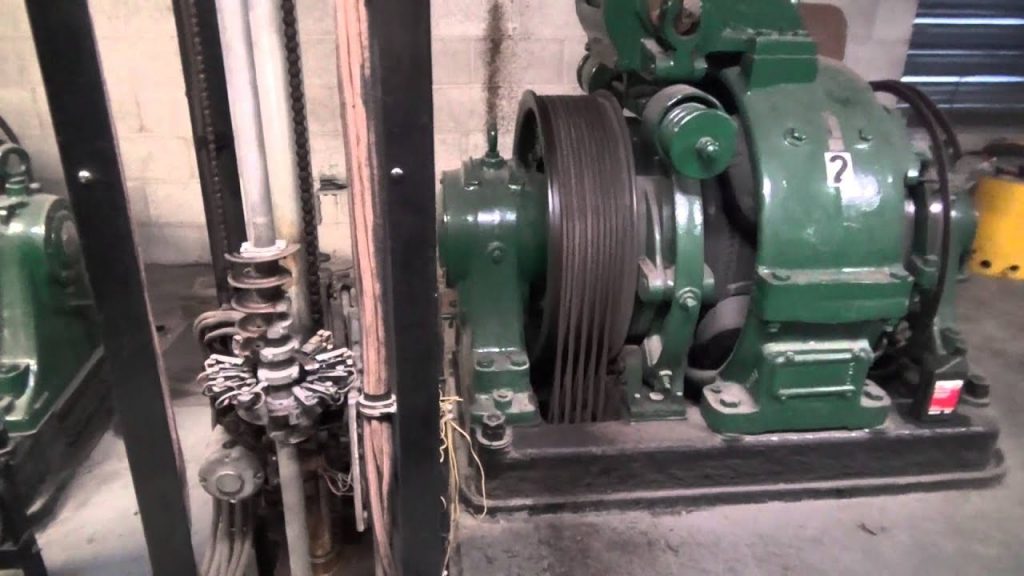

- Machine room:The machine room is otherwise known as the lift room. It appears to be on the top floor above the shaft. The integral component of the elevator is the drive unit, Motor, Control Panel. With the advancement of technology, the machine room is getting smaller and smaller. Some elevators like Machine room fewer elevators install the machine room in the shaft itself.

- Guide rails:These are generally made up of steel. And it is in the shape of T. These are placed vertically between the shaft to guide and direct the travel of an elevator car and elevator counterweights.

- Drive Unit:The drive unit is placed in the machine room. It is used to regulate the Speed, Torque, and Movement of an elevator. If your elevator often suffers from slow starts and stops or seems to make sharp, sudden jerks, then the drive could be to blame.

- Control unit: It is also known as a controller or control panel. The control unit is placed at the machine room top of the elevator shaft. When we press any button in the lift, it goes to the control unit, and then it is transferred through the system to tell the motor whether to move up or down.

Once the elevator has reached its destination, there’s a signal sent to the control room to either stop and let the passenger board or exit it.

- Counterweight:The unit consists of steel weights that counterbalance the car’s weight and the attached suspension ropes. Counterweight makes it easier for the motor to raise and lower the car.

For example, if you are sitting in a seesaw. The seesaw is correctly balanced so that you can go up and down, any number of times without ever really getting tired, which is different from lifting someone in your arms that tires you faster. Hence, the motor needs to use much less force to move the car either up or down.

Suppose the lift is filled with a total capacity which means it takes more than the counterweight, but in this case, the motor has to lift the difference in weight between the two and supply a bit of extra force to overcome friction in the pulleys. Since less force is involved, there is less strain on the cables, making the elevators a little safer.

- Guide shoes:Guide shoes are the devices that are used to guide the car and counterweight along the path of the guide rails. There are two types of guide shoes such as roller guides and sliding guides.

The roller guides use rollers that rotate on guide rails. It has a set of three wheels that roll against the guide rails. Guide shoes slide along the faces of the rails. The sliding insert may be metal requiring guide rails to be lubricated or maybe self-lubricating plastic material.

Benefits of Gearless Elevator Machines

These are several significant benefits of choosing gearless elevator machines. Few of them include

- Small in size

- 40% less power consumption

- Lightweight

- Zero maintenance

Conclusion

Do you know why the lift is often called a Car? It is because the lift also does the same work as the car does. The car also has less capacity, and the lift can also allow only limited members. Thus, lift and car both help us to travel from one place to another.