Stainless Steel is a component of outstanding mechanical characteristics and is available in various grades. Certain grades of stainless steel have the added advantage of excellent corrosion resistance, and some grades are heat treatable which further enhances mechanical and carrot resistance characteristics.

These are just a few reasons why stainless steel is used today to produce various casting foundries India materials for commercial and industrial investments.

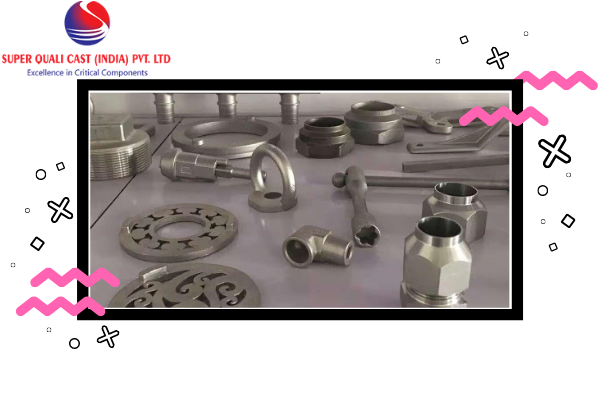

Stainless steel investment castings manufacturers have considerable experience in manufacturing investment casts in different shapes and sizes from a wide range of stainless steel alloys.

Casting in Stainless Steel – What’s it made of?

Chromium, nickel and molybdenum (or “moly”) are the base alloy materials for both nickel base and stainless steel casts. These three components decide the grain structure and mechanical prosperity of CNC Turned Castings India and play an important role in fighting heat and corrosion.

Stainless steel is 10.5% less chromium, making it more resistant to corrosive fluid and oxidation conditions. So it’s not complete. Investment casts in stainless steel have “corrosion resistance” in liquid environments and vapours below 1200°F (650°C) and, if used above this temperature, are “heat-resistant.”

Differences exist between the wound and cast stainless steel models. This is because of its chemical composition and its micro-grain structure, which is influenced by the way the material is made, cast or extruded. When selecting an alloy for your investment cast metal stainless steel project, these considerations must be considered.

Investment capacity in Stainless Steel. The following investments help us better serve customers:

- Size: Using the air melt method, all stainless steel grades are poured up to 25 lb of small bits. Pieces. Parts.

- Variability: It will improve the processes to handle complex and complex investment-cast component designs.

- Higher and Lower Volume: We can manufacture a small number of cast parts for proof of concept during the year, to thousands.

Stainless Steel Investment Casting Benefits

- The greatest advantage of Stainless Steel is its good corrosion resistance. Unlike other materials, stainless steel investment casts have an integrated chrome oxide coating with excellent anti-corrosive properties. These corrosion-resistant properties make inox casting suitable for military, medical and manufacturing uses. Investment casting in oxidable steel is used in a wide variety of sectors of industry for the following reasons:

- Good corrosion opposition: Chromium is used as a stainless steel alloy that improves its bashing properties. Compared to carbon and alloy steel, stainless steel castings need little or no surface finish. That’s why investment casts in stainless steel are used in industrial components such as pumps, valves and other parts that need critical corrosion resistance.

- Exceptional visual quality: Rank A overall impact is possible for the high visual quality investment cast pieces.

- Surface finishing: Easier to reach 120 RMS or better

- Near tolerances: tolerance levels of ±.005 inch per inch can be reached.

- Near Net Form Components: stop long-term use of near-net investment cast parts for machine parts.

Applications of Stainless Steel Investment Castings

- Marine Application: Stainless steel projecting is utilized in marine applications that require substantial parts with amazingly high protection from warmth, scraped area, and erosion. CFS foundry utilizes a wide scope of hardened steel combinations for sporting, administrative and business marine parts. Hardened steel marine castings can be cleaned to a mirror finish for the greatest erosion and scraped spot obstruction. New marine evaluation tempered steel speculation castings for marine application could be provided electro cleaned and machined from their current spend.

- Pipes Fittings: Pipe Fittings are segments utilized for interfacing, ending, controlling stream, and altering the course of funnelling in a wide range of ventures. When buying pipe fittings, thinking about the application, these line fittings are ordinarily made of treated steel 316, which is higher strength and more erosion safe than hardened steel 304. Hardened steel projecting is the most practical strategy for little volume creation.

Stainless Steel Investment Castings is known when both steel properties and corrosion resistance are essential. Besides the following sectors, stainless steel investment moulds can be used for various applications:

- Petrochemical goods

- Agriculture / Food business

- Aerospace field

- Energy sector

- Automotive

- Military

- Guns of fire

- The Machine Tool