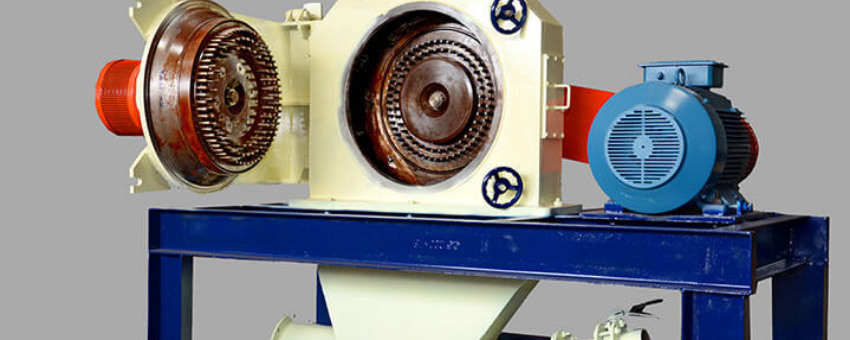

A pin mill is a type of impact mill where particles are broken down with the force of an impacting object. The impacting object hits the particles with heavy force, breaking them down. The repeated motion of the mill breaks the particles further into smaller and smaller pieces till we have the right size. The advantage of pin mill is that it can break up cellular materials in a manner that does not damage its starch granules.

With technology favoring pin mill exporters, it is considered one of the best milling techniques today. Not surprisingly, it is one of the most used grinding mills today. It can process a large number of materials, grinding them to a very small size. But before you buy a pin mill, you must evaluate your requirements and calculate the correct specifications. Doing so would not only optimize your mill performance, but also reduce the need for part replacement and repair.

Here are the factors you have to keep in mind when ordering a pin mill:

Emphasizing on quality

A pin mill is an intensely impact-based operation. This causes heavy wear and tear on the parts. That isn’t all. A poor quality pin material or lining will quickly start to chip and the flakes can contaminate the prepared result. The consequences of poor quality parts can be disastrous in the final analysis. It will mean frequent repair and breakdown of the mill. It can bring the entire production to a standstill, causing loss in lost production and labour, apart from maintenance and parts cost. Eventually, you will have to order new parts.

The parts where you must pay extra attention are wear parts. These are the parts that see the maximum wear and tear. This will include all internal parts that are in contact with the grinding process, including the pins, rotor, wear plate, and the impact wall at the wear plate’s periphery. These parts are actively engaged in the grinding process. The pins hammer the product, the rotor, wear plate and the impact walls are constantly bombarded by the grounded particles.

Apart form the wear and tear from the impact, there could also be other damaging factors like corrosion. If the mill handles corrosive materials, the wear parts will eventually start to corrode. The material of the wear parts should therefore, be strong enough to weather the conditions, while staying resistant to any corrosive elements. There are a number of compositions offered by pin mill exporters today to meet these two requirements. Steel with anti-corrosive coating is one of the most popular options.

Number and arrangement of the pins

The number of pins and their arrangement can be specified. The usual arrangement is in rows. The right number of pins and their arrangement helps us to get the right particle size along with the desired distribution.We can get a very precise distribution with the narrowness we want. It can also help us to minimize the material buildup in the mill during grinding. By controlling the material distribution, we can control the contamination and the frequency of washing the mill and the associated downtime.

The movement of the pins generates heat within the mull. The number of pins should therefore, be calculated on the basis of heat generated during the grinding. This can help in avoiding heat buildup which can cause the softening of the material, particularly heat-sensitive materials. You can take the pin mill manufacturer’s counsel in determining these two factors.

Ordering spare parts

This is just basic common sense. Even with the best of parts, wear and tear is inevitable. Parts will start disintegrating or just coming off. You can order replacements from your suppliers, but this would take time. Delays will result in expensive loss of production and unproductive labour costs. If the parts are built to specifications and not standard, the delay can cause damaging halt of production.

This is why many manufacturers order spare parts from pin mill exporters. This would ensure that there is a ready availability of replacements and minimal loss of work. It can also give you crucial time to tide over till you order other parts or repair the damaged parts. If you intend to change your supplier, the availability of spare parts can also give you a prototype to work with.