Tensile testing is also known as tension testing. It is a test of material science and engineering. The tensile test is the most fundamental type of tension test. In this test, the sample is applied to a controlled tension till failure. A tensile test is the simplest test which is mostly used as the mechanical test. Tensile testing is commonly used to obtain the mechanical characteristics of the materials which are isotropic in nature.

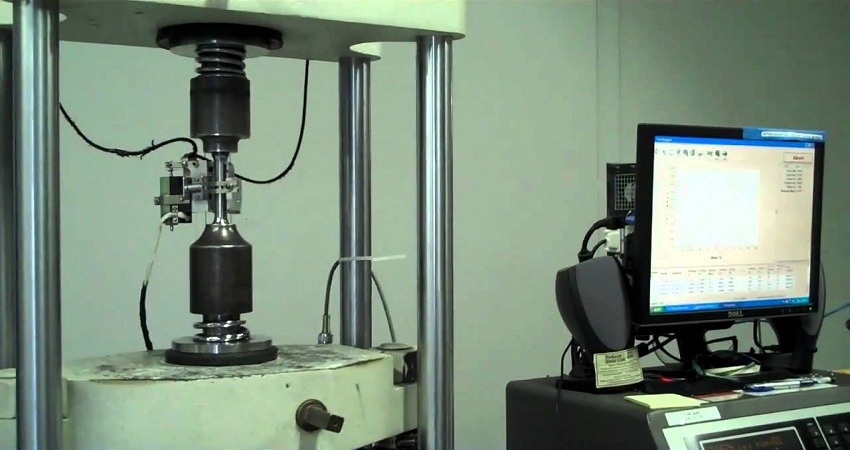

This test is done under controlled conditions to determine the tensile properties of the material. It is mainly used to determine the tensile strength or we can say that it is used to determine the maximum load that a material or a product can suffer. The Tensile Testing Machine manufactured at EIE facility, is used to test the tensile strength and compressive strength of the material is the universal testing machine (UTM). This machine is also known as the universal tester.

This type of machine has two blocks. First is used for adjusting the length of the specimen and the second is used to apply the tension to the specimen which is testing. The machine must have the proper capabilities to test the specimen. There are two types of machines, which are:

- Hydraulic Powered machines and

- Electromagnetically Powered machines.

There are four main parameters of the machine that are –

- Force capacity

- Accuracy

- Speed and

- Precision

As engineers of EIE know that the brittle metals are more likely to be crack so this tensile testing is an important factor in metal to form the process. Tensile tests are simple as well as fully standardized and also economical. The properties that are directly measured by using tensile tests are the ultimate tensile strength, breaking strength and reduction in area. Tensile testing has various purposes. Some of them are:

- Tensile testing predicts that how a material will perform in use.

- Tensile testing selects a material for an application.

- It also provides a basis for technical communication.

- Tensile testing decides a new product development program is on track or not.

- It provides the evidence in legal proceedings.

Tensile testing is carried out at a material testing laboratory. The most common tensile testing protocol is ASTM D638. ASTM D3638 measures the plastics tensile properties which include ultimate tensile strength, elongation and yield strength. There are four types of tensile testing which are given below:

- Tear Resistance

- Peel

- Adhesion/Bond Strength

- Crimp Joint Pull-off Force

There are the benefits of all the products, the test that we have. Tensile testing is also having benefits. Tensile testing provides the data on the safety of materials, components, items, and products. The data which is produced in this test is used in many ways which are given below:

- To determine batch quality.

- To aid in the design process.

- To ensure compliance with industry standards.

- To determine the consistency in manufacturing.

- To reduce material costs.

- To achieve manufacturing goals.

Now let’s talk about some applications of tensile testing:

- Tensile testing is used in the Aerospace industry.

- It is also used in the Automotive Industry.

- It is used in the Beverage Industry.

- It is also used in the Medical Device Industry.

- Tensile testing is also used in the Construction Industry.

- It is used in the Textiles Industry.

- Tensile testing is used in Electrical and Electronic Industry.

- Tensile testing is used in Safety, Health, Fitness and Leisure Industry.

- It is used in the Paper and Board Industry.

- It is also used in the Packaging Industry.

- Tensile testing is used in Plastics, Rubber and Elastomers Industry.

- It is used in the Pharmaceuticals Industry.

Each tensile testing machine manufactured by EIE engineers is an important asset of the industry that plays a crucial role.