The striking thing about technology is that it can be both wonderful and tragic. Electricity is one of these wonders. All the gadgets, appliances and machines will not work without some kind of electrical support somewhere. It is wonderful in its ability to transform our life. But when left without any checks, it can wreck havoc, causing fire and destruction.

One of the safeguards we need is insulation. It is required in electrical cables to support and separate conductors or wires inside it. The main job of the insulating material is to ensure that the conductors stay separated and there is no contact. It reduces the chances of overheating by friction. There are many materials used for insulation, such as PVC, XLPE and even paper. PVC cables manufacturers are among the most preferred because of the advantages that PVC offers.

Insulation

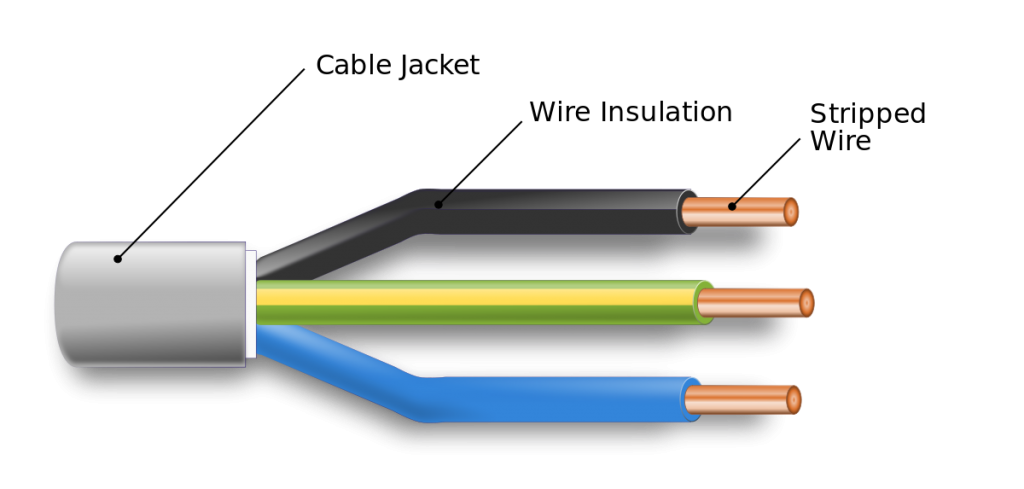

A conductor in a cable transfers electricity from one point to another. For this reason it is made of a highly conductible metal like copper or aluminium. But this also makes it quite dangerous. An open wire is literally a live wire that is humming with electric current. What happens when we leave it without any insulation in a cable? The highly charged wires would rub against each other, overheating almost instantly. Even a single conductor cable if left uninsulated, will completely expose the wire within.

Insulation, hence, separates the conductors by keeping them wrapped. It also helps in reducing any leakage of electricity from the wire within. It also keeps the conductors safe from exposure to environmental factors. Without it, the wires will be exposed to sun, rain and other corrosive materials like chemicals present in the atmosphere.

To do its job, an insulator must be exactly the opposite of a conductor. In theory, an insulator should not carry any electric current. However, there is really no ideal insulator because every material has some kind of resistance. But for our purposes, we simply need a material with extremely high resistance. Popular insulation materials like PVC, XLPE and rubber carry such qualities. From a manufacturing point of view, we need a material that has high resistance and can be manufactured economically at an industrial scale. For instance, PVC’s popularity is also in part because technology allows the PVC cables manufacturers to produce these at an economical cost.

Types of insulation material:

The three more commonly found insulation material are plastics, fluoropolymers and rubber. Materials like teflon, paper, ceramic and even oil is used sometimes. Let us look at the first three materials:

Plastics

This includes thermoplastic and thermoset plastics. The former includes PVC,PE, PVDF, ECTFE and Nylon. Thermoplastic is tough yet pliable. However, it will melt when subjected to high temperature. This is the most commonly found insulation, especially PVC. The reason for PVC cables manufacturers high sales lie in the material’s durability, wide availability and affordability.

The advantage of thermoset plastics over thermoplastic is its resistance to high temperature. It can maintain its shape even under thermal expansion. Thermoset plastics include XLPE, EPR and CPE.

Fluoropolymer

Fluoropolymer is a fluorocarbon-based polymer. It is preferred for its ability to withstand a wide temperature range. It is also known for its high resistance to corrosive factors like solvents, bases and acids. It also has unique electrical and mechanical properties that make it suitable for insulation. It includes PTFE, PFA, FEP, and ETFE. It has high non-stick properties, which is useful in reducing friction. It is also highly stable. The manufacturing technology is still improving and it is expected to grow significantly.

Rubber

The electrons in a rubber molecule are tightly bound and cannot be taken apart easily. It is this property that makes rubber such an excellent insulating material. Its elasticity and resistance to water add to this quality. Both natural and synthetic rubber has been used for insulation. Although, today it is the synthetic rubber that is used for the purpose. Examples include, Thermoplastic Rubber, Neoprene, Silicone, Fiberglass, SBR, EPR, CSPE, and Rubber.

These are the various types of cable insulation. PVC continues to be the most preferred with PVC cables manufacturers supplying to a wide range of industries.