INTRODUCTION

Steel valves are crucial in oil and gas production, water treatment, and power generation. Steel valves control liquid and gas flow and need accurate engineering, high-quality materials, and innovative technology.

Sagarvalve leads this sector with high-quality steel valves that fulfil strict safety and performance criteria. The following blog investigates steel valve manufacturing, starting with its manufacturing techniques and ending with its product applications and key manufacturing elements.

What Is Steel Valve Manufacture?

Steel valve manufacture refers to designing, producing, and testing valves made from steel alloys. The piping system requires these valves to regulate fluid and gas movement. The initial manufacturing step demands selecting appropriate steel materials from three main categories: carbon steel, stainless steel, and alloy steel, according to the intended application. The manufacturing sequence includes steps for casting and then machining before heat treatment and quality cheques.

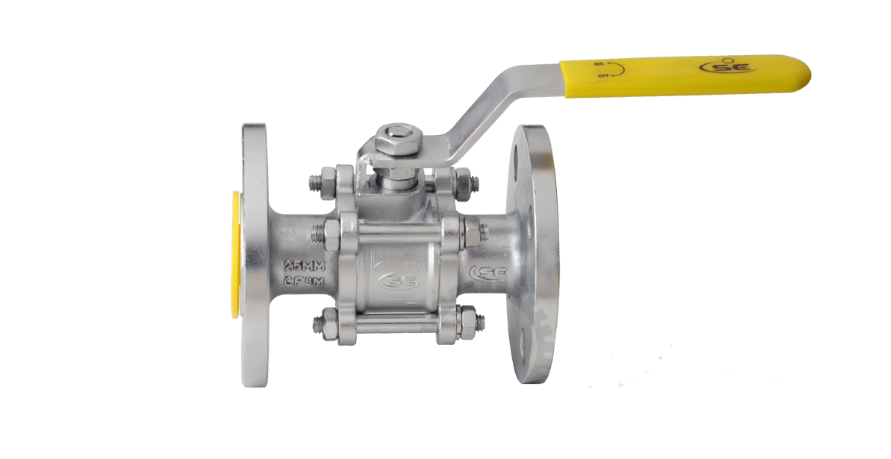

The steel valve sector uses functional categories to name its products (ball valves, gate valves, globe valves). It produces these items at different pressure levels while handling particular temperatures and media types. Quality control is paramount for a company like Sagarvalve, ensuring that each valve meets domestic and international standards.

Materials Used in Steel Valve Manufacture

The material selection process is a crucial aspect of steel valve manufacture.

The fundamental materials for making valves include steel alloys, which consist of carbon steel, stainless steel, and alloy steel.

- Carbon steel

The strength and durability of carbon steel make this type of steel suitable for valves when operating at low pressures.

- Stainless steel

Stainless steel valves stay corrosion-free, thus solving problems with both high-pressure operations and chemical resistance.

- Alloy steel

The manufacturing process of alloy steel valves aims to achieve high-temperature and high-pressure suitability while sustaining resistance in extreme conditions.

Selecting appropriate materials becomes critical because it will enhance valve lifetime and operational performance within designated operational environments.

The Manufacturing Process of Steel Valves

The steel valve manufacturing process is intricate and requires specialised knowledge. Here’s a brief breakdown:

- Casting:

Manufacturing of the valve body starts by pouring the selected steel alloy through casting procedures. An initial step includes pouring molten steel into a mould before the solidification phase during the cooling process.

- Machining

The production continues with machining steps to accomplish exact specifications after casting the valve. The manufacturing techniques include turning, milling and grinding to make the internal passages and fitting surfaces.

- Heat treatment

The valve receives heat treatment following machining to enhance its strength and hardness. The required material features influence which heat treatment approach will be utilised – it might be annealing, tempering or quenching.

- Assembly

The assembled valve components, which consist of the body, bonnet, stem, and actuator, receive heat treatment in the following order. Each valve functions smoothly and reliably because of this process.

- Testing and quality control

The valve undergoes strict tests as part of quality control procedures to validate its performance compliance. The testing procedure includes pressure testing combined with leak testing and fatigue testing.

Factors to Consider in Steel Valve Manufacture

When manufacturing steel valves, several factors come into play:

- Application Requirements: Understanding the specific requirements of the application (e.g., pressure, temperature, media type) helps determine the right design and materials for the valve.

- Type of Valve: The industry would affect the design and operation of valves. Gate, globe, check, and ball valves are popular.

- Standards and Certifications: Valves must follow international standards such as ANSI, API, and ISO to be sure they fulfil safety and dependability criteria.

- Quality Assurance: Tight testing and better manufacturing techniques ensure the lifetime and effectiveness of every valve. Companies like Sagarvalve strongly emphasise quality control to avoid defects and maintain the highest standards.

- Cost and Lead Time: Cost-effectiveness and timely delivery are essential for valve manufacturers. Balancing quality with cost considerations ensures competitiveness in the market.

Applications of Steel Valves

Steel valves exist in countless production sectors and are used in different applications. Several prominent applications use steel valves, among which are:

- Oil and gas

The oil and gas industry heavily depends on steel valves to manage fluid flows through oil pipelines and refinery systems.

- water treatment

The flow of water and chemicals during water treatment is managed through steel valves, which are common across these plants.

- power generation

The operation of power plants requires steel valves to monitor steam along with water and fuel flow for efficient production and safety prevention.

- Chemical processing

The chemical processing sector employs steel valves to regulate the transportation of corrosive fluids alongside high-temperature contents during safe operational procedures.

The Role of Steel Valve Manufacturers like Sagarvalve

By manufacturing valves that satisfy worldwide criteria for safety, performance, and durability, companies such as Sagarvalve are indispensable in the steel valve production sector. These producers commit to research and development to create creative valve designs and enhance manufacturing techniques.

Companies such as Sagarvalve guarantee that sectors can access dependable and reasonably priced valves by providing tailored solutions and upholding a dedication to quality. Furthermore, they stay ahead of market demands by adopting new technologies, such as smart valves and automation systems, which enhance operational efficiency.

Benefits of Steel Valve Manufacture

Multiple industries gain multiple advantages through implementing steel valves.

- Durability:

Steel valves demonstrate excellent durability properties because they can withstand harsh environmental conditions for extended periods.

- Resistance to Corrosion:

Stainless steel and alloy steel valves effectively withstand corrosion, thus becoming suitable for harsh chemical settings.

- High Pressure and Temperature Tolerance:

Steel valves show high tolerance to extreme conditions, including elevated pressure and temperature fluctuations.

- Customizability:

Steel valve manufacturers offer customisation options, ensuring valves meet specific industry requirements.

FAQ

- What is steel valve manufacture?

Design, manufacturing, and testing of steel valves used for varying industry control of fluid or gas flow constitute steel valve production.

- Which materials are usually utilised in the production of steel valves?

The major production materials used for steel valves are carbon steel, stainless steel, and alloy steel.

- What are the common applications of steel valves?

Steel valves serve diverse applications across the oil and gas sector, water treatment, power generation, and chemical processing.

- How do manufacturers ensure the quality of steel valves?

Manufacturers conduct systematic tests of pressure and leaks that help determine whether valves fulfil their safety requirements and operational standards.

- What are the benefits of using steel valves?

Steel valves present industrial operations with durability, corrosion protection, high-pressure tolerance, and design flexibility for different industrial uses.

Conclusion

Steel valve manufacture is complex and requires precise engineering, high-quality materials, and cutting-edge technology. Steel valve manufacturers are more important as industries expand and need high-quality, lasting valves. Sagarvalve continues to offer innovative solutions to fulfil market demands.The entire spectrum of industries benefits from steel valves by delivering secure systems with reliable performance and efficient operations. Companies need excellent steel valves for their processes. Your operations will run more efficiently with the premium steel valves that Sagarvalve provides. Contact us right now to receive top-quality solutions from our team of experts.