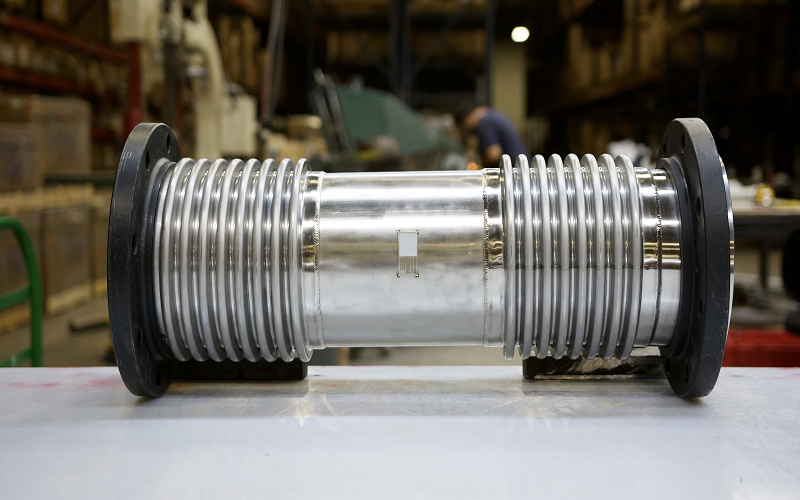

Expansion below joints is made up of those unique piping system parts that can be applied to fit in thermal expansion and contraction, ensuring it is done in a smooth operation without causing any harm to the piping system. Spool wheel-like joints have edges threaded to ensure two pieces come together strongly, making them perfectly suited for elaborate configurations into oil and gas as well as HVAC. The design allows it to easily integrate as well as providing a tight seal without allowing leaks. Since expansion bellow joints make it possible for the system to have flexibility in absorbing movement, it thus makes them necessary for reliable performance in demanding environments while also improving the integrity and efficiency of a given system.

What is meant by Expansion bellow joint?

The expansion bellow is that type of pipe joint made spool wheel that is provided with threaded edges at either or both ends to securely connect the pipes of any complex piping system. This facility is designed to easily integrate and install it accommodating multiple sizes of pipes as well as configurations. Since the edges are threaded, this pipe joint allows for a very tight seal without leaking but provides the flexibility needed to absorb thermal expansion and contraction. Being an expansion joint, it acts as a buffer between rigid components, allowing for more fluid movement and alignment, which is important to maintain system integrity under changes in temperature and pressure. This functionality renders it an indispensable component within intricate piping setups where reliable performance becomes the cornerstone of overall operational efficiency.

Who manufacturers Expansion bellow joint? How are Expansion bellow joints manufactured?

The companies specialized in designing flexible piping solutions for major industries-be it oil and gas or chemical processing, HVAC, and power generation-manufacture expansion bellow joints. In general, the manufacturing process includes the following steps: high-quality material for use-mostly stainless steel or rubber-is selected in line with specific requirements of the application. Advanced techniques such as deep drawing or hydroforming must allow the bellows flexibility and strength. After forming, welding, testing, and quality control ensure that the production meets industrial standards with regards to durability and performance. Lastly, the expansion joints are assembled with their end fittings, consisting of either flanges or threaded connections, for easy fit up in complex piping systems. A reputed Expansion bellow manufacturer performs careful manufacturing process that ensures expansion bellows joints are reliable and durable in performance, where demanding environments call for such usage.

What raw materials and modern machines are required for Expansion bellow joint manufacturing?

Expansion bellow joints need high-quality raw materials and modern machinery for reliable and effective manufacturing. Among the common raw materials used, stainless steel, very resistant to corrosion with significant strength, is a prominent one; rubber or elastomers, providing elasticity as well as sealing action; and, in some cases, specialized alloys are used when there are specific requirements. This involves the application of high technology, such as deep drawing presses in shaping the bellows, laser cutting machines in very specific profile shaping, and CNC machining centres for accurate end fittings. The welding equipment is used to join together various parts safely and securely, and the testing machines will ensure that the produced goods pass through stringent test of the quality standards regarding pressure and temperature resistance. The combination of such materials and machines allows the Expansion joint bellows manufacturer to produce reliable and efficient expansion bellow joints for different industrial applications.

What are main benefits of Expansion bellow joints?

Expansion bellow joints have several characteristics that improve performance and reliability in piping systems. Thermal expansion and contraction are allowed, thus reducing pipeline stress, misalignment, and even failure. Flexibility extends the life of the system and reduces maintenance, since repairs occur less frequently. Additional expansion bellow joints may absorb lateral, axial, and angular movements, hence accommodating many sophisticated piping configurations. They are also vibration dampeners that minimize noise and wear out associated with connected parts. Installation translates into better efficiency since the system would maintain proper alignment and leakage reduction, among other things. Overall, the expansion bellow joints in piping contribute much to safety and efficiency in all operations of industries.

Conclusion

These are integral components that significantly increase the reliability as well as efficiency of piping systems in different industries, designed uniquely to absorb thermal expansion and contraction without any stress or failure in pipes. Advanced manufacturing processes coupled with high-quality materials as well as modern machinery for the same ensures that it would endure for years in these joints. Expansion bellow joints enhance the safety guarantee of the operating procedure by ensuring smoothened motion and proper angulation for longer periods without maintenance costs, thereby enhancing efficiency in the system. The understanding of their function and benefits makes their utilization indispensable for integrity in complex systems.