Pipe expansion joint helps the water pipelines, sewage pipelines to sustain atmospheric harsh conditions like cold or hot weather which causes contraction and expansion of pipe materials depending on the materials they are made from. Expansion joint help us to control the movement of the fluids like oil, water, or gas etc. In this article we will explore advantages of pipe expansion joint in India.

What is meant by pipe expansion joint?

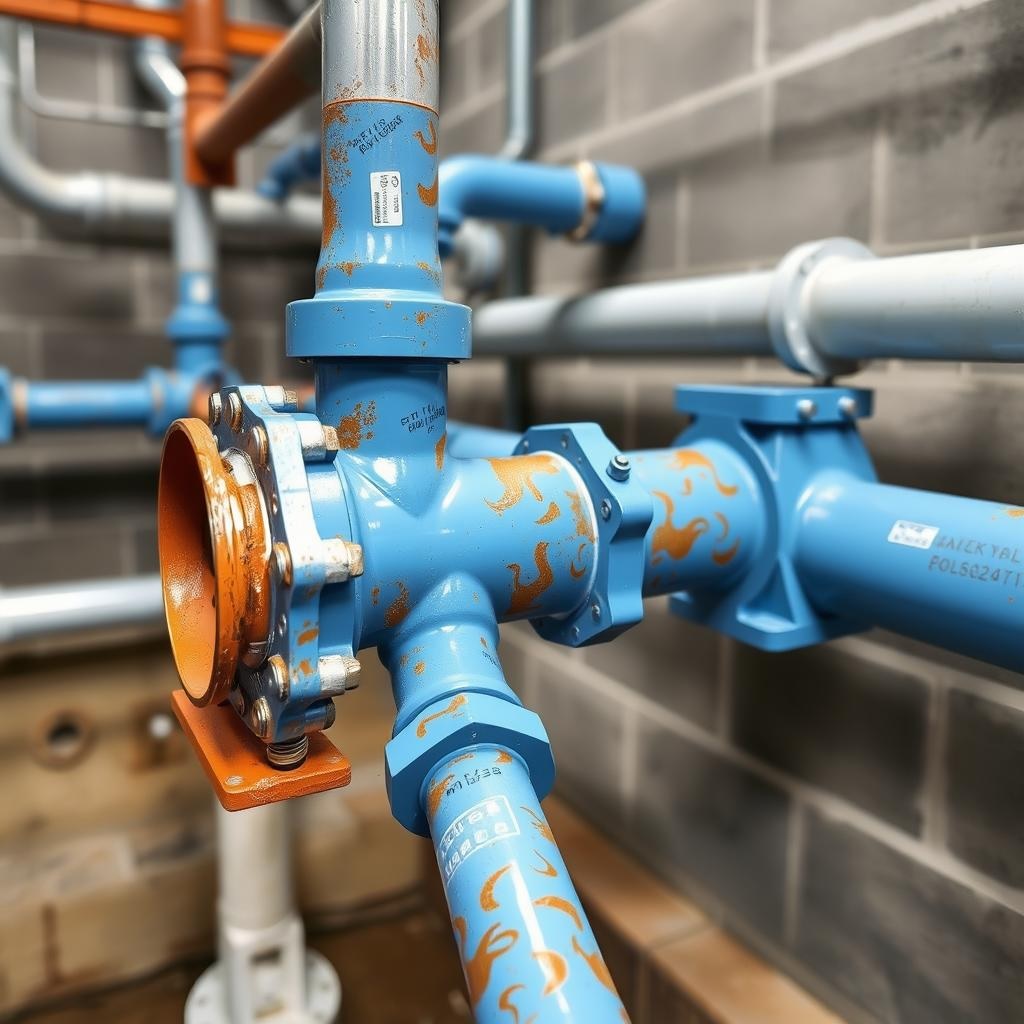

Pipe expansion joint is a flexible connector put in piping systems to absorb thermal expansion, contraction, or other movements resulting from a change in temperature, pressure, or mechanical forces. These prevent stress and pipe damage due to the controlled movement to axial, lateral, or angular shifts. Pipe expansion joints come in different materials such as metal, rubber, or fabric. These are very important pipelines in a lot of industrial applications, in that they prevent the cracking, leakage, or failure of pipelines due to the stress caused by external forces.

Why do we need pipe expansion joint?

A flexible piping connection that is installed in piping systems to absorb movements resulting from thermal expansion, contraction, or other movements related to temperature increases, pressure, or mechanical forces is a pipe expansion joint. These joints prevent stress and damage to the pipes by allowing controlled movements such as axial, lateral, or angular shifts. Made from metals, rubber, or fabrics, the pipe expansion joints are typically used in industries to maintain the integrity and long life of pipelines. They help with cracking or leakage and failure by settlement stresses and normal thermal expansion which is caused by excessive shrinkage.

How are pipe expansion joint manufactured?

Expansion joints are manufactured precisely with materials which may be metal, rubber, or fabric in relation to the application and environmental conditions. With the same application and conditions, it starts the process of cutting and forming sheets of steel and other metals into a bellows-like shape, which is then welded or hydraulically formed to flexible sections. The joints are made of rubber and fabric that are moulded or layered together to provide flexibility alongside durability. The bellows would then be designed with some specific movement and pressure in mind. Additional features such as flanges, end fittings, and tie rods are added for easy access and structural strength. The product assembled will then go through extreme quality testing, durability testing, and performance testing before it is considered acceptable for use within industries.

What quality control measures must be kept by pipe expansion joint manufacturers in India?

Manufacturers of pipe expansion joint India must insist upon proper quality control measures. Therefore, they have to ensure safety, durability, and reliability while manufacturing the item. This can be achieved by choosing superior-grade raw materials meeting every criterion defined by the industries along with thorough checks at each stage of production. Suitable testing should be done regarding pressure performance, fatigue, and temperature resistance tests for warranting the reliability of the joint to withstand operational stress. Due to the fact that maintenance of flexibility and structure are accomplished in welding or moulding processes, proper alignment and accuracy are essential. Moreover, manufacturers should follow international standards like ASTM, ASME, or IS and should maintain any type of documentation and traceability of every product lot so that quality is ensured constantly in the course of production.

What are the benefits of using pipe expansion joints?

Pipe expansion joints offer several key benefits in industrial piping systems. Pipe expansion joints offer many benefits in industrial and commercial piping systems. They absorb thermal expansion and contraction of the pipelines during extreme harsh weather condition when the temperature is too hot or too cold. They also prevent the pipelines from mechanical shocks and breakage eliminating the risk of leakage due to mechanical jerks during earth quake.

Conclusion

To sum up, we must say that pipe expansion joints are essential elements in ensuring the efficacy and extending the lifetime of piping systems within Indian fields. Along with the ability to expand thermally while redistributing stresses and vibrations, they have become indispensable in a variety of industries, starting from pipes for water and sewage to conveying oil and gas. These joints accommodate the effects of temperature fluctuations and mechanical forces to prevent leaks, cracks, and costly damage to ensure smooth operations even in tough environmental conditions. Quality manufacturing, proper installation, and international standard of pipe expansion joints continue to dictate industrial applications as industrial applications continue to evolve for sustained success in India’s infrastructure and industrial growth.