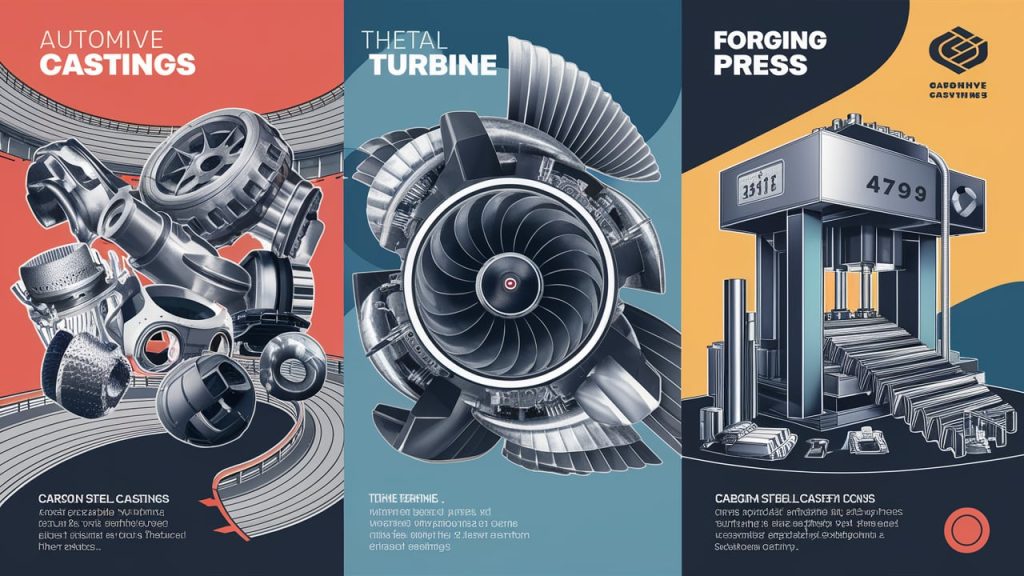

In the pursuit of innovation and excellence, industries across the globe are constantly seeking ways to improve their products and manufacturing processes. One material that has emerged as a game-changer in various sectors is carbon steel casting. With its unique combination of strength, durability, and versatility, carbon steel castings manufacturers have been making significant waves in the automotive, turbine, and forging press industries.

From engine components and gearboxes to turbine blades and press molds, carbon steel castings are revolutionizing the way these industries produce and operate. But what makes them so special? In this post, we’ll delve into the benefits of carbon steel castings, exploring their advantages in terms of performance, cost, and sustainability, and highlighting the industries that are already reaping the rewards of this cutting-edge technology.

What Is Carbon Steel?

- When it comes to steel castings, carbon steel is one of the most important elements that may be used. On the basis of the amount of carbon that they contain, carbon steels may be divided into the following categories:

- A wide variety of tensile qualities may be achieved with heat treatment for low-carbon steels (with a carbon content of less than 0.20%). These steels can also be hardened to provide high surface hardness, abrasion resistance, and strong core ductility.

- The composition of medium-carbon steels, which range from 0.20 to 0.50% carbon, makes it more durable, flexible, and stronger than other types of steel. In the softened state, it is feasible to achieve a wide variety of tensile strengths, including high ductility and shock resistance, and it may be machined with relative ease.

- Strong and having an excellent shape memory, high-carbon steels (those with a carbon content more than 0.50%) are an alternative that spring makers find especially beneficial. The alloy steel that is used for high tensile applications is susceptible to wear and abrasion, and it is also suited for use in heavy-duty applications.

Casting is one of the fundamental procedures that is used in the process of shaping steel. Both in terms of cost and manufacturing time, it is a cost-effective option. Cast steel is used in the production of a wide variety of components due to the many benefits associated with the process.

Some Of The Advantages By Carbon Steel Castings Manufacturers Are Mentioned Below:

- As is common knowledge, carbon steel is not only more durable than stainless steel but also much more affordable. Carbon steel castings, on the one hand, are uncomplicated to get and might be mixed with one or more alloying components to make them simple to personalise. The castings made of carbon steel, on the other hand, may be produced to be very thin. Thus, we may save prices by using a smaller amount of material.

- Due to the fact that it has ferromagnetic characteristics, carbon steel is advantageous for use in motors and electrical equipment. A high degree of structural integrity is present in this alloy, which is also safe and long-lasting.

- In the first place, carbon steel castings are not only robust and long-lasting, but they also have the ideal composition for the majority of tasks. We are able to process mild steel in an effective manner into any form or standard that may be imagined.

- In addition, carbon steel castings are often used in turbine components that call for a high level of accuracy and strict tolerances. These components include blades, diffusers, and impellers on turbines. Castings made of carbon steel have the capability of producing precise features and complicated geometries, which enables the production of high-performance components that are able to survive the harsh circumstances that are present during turbine operation.

- Castings made of carbon steel are also well-known for their resistance to corrosion, which indicates that they are able to tolerate severe environments and extreme circumstances without deteriorating or breaking down. This not only increases their longevity but also decreases the frequency with which they need to be replaced, which further minimises the amount of trash produced and the effect on the environment.

Conclusion

Get in touch with carbon steel castings manufacturers for your casting requirements by contacting us. Do not worry if the grade of your castings still confuses you; their material expert will suggest the best course of action.