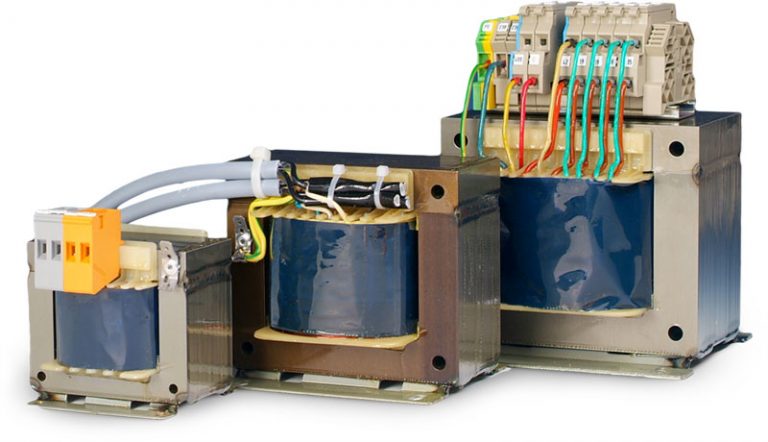

Transformers come in different sizes and types as per the user’s demand. Power Transformers Manufacturers India designs industrial control transformers for industrial applications that need relays, solenoids, and other electromagnetic devices.

These transformers have capacitors or other filtering devices to lower variations in output and are ideal for applications that need constant current or voltage with a low power rating or low volt-amp.

Control transformers made for industrial purposes are insulated and impregnated with a vacuum, often with a polyester resin.

Manufacturers apply the oven-curing technique to seal the transformer surface and eliminate moisture. They also sell waterproof, weather-resistant, and other specialized products to customers around the globe.

Major performance specifications

Major performance specifications for control transformers used by industries include-

- Operating temperature

- Power rating

- Maximum primary and secondary voltage rating

- Operating frequency range

- Minimum voltage required

Industrial control transformers differ in output voltage, phase, and winding turns.

Phase

Manufacturers provide choices between phases to their customers. The buyers of control transformers can use the models in single-phase and three-phase (polyphase).

Output Voltage

The manufacturers provide two choices for output voltage – alternating current (AC) and direct current (DC)

Winding turns

Manufacturing units of transformers provide four choices for winding turns to their clients-

- One-to-one industrial control transformers that have a turn ratio of 1:1 or near 1:1

- Variable transformers include a setting with which users can change the turn ratio as per the need

- The secondary voltage is larger than the primary voltage in the step-up transformer model

- The secondary voltage is smaller than the primary voltage in step down transformer model

The use and application of industrial control transformers are necessary for control devices’ reliable and safe operation.

Electromagnetic control components like contactors, solenoids, and timers place bulk demands on transformers.

Transformer Testing

There are multiple checks and tests performed as a transformer is being done at the substation.

The working engineer may not directly run all of the tests and checks, but he must ensure that all checks are completely done.

The professionals follow some tests and procedures during the assembly phase. Some tests areas are listed below-

- Auxiliary components and wire checks

- Hand meggering

- Lightning arrestors

- Temperature devices

- Nameplate data

- Power meggering

- CT tests

- Bushing power factoring

- Cooling system

- Trip checks

- Polarity

- Tap changes

- Voltage ratio

- Zero sequence

- Winding resistance

- Auxiliary power

- Overall loading

- Remote temperature indication

The experts inspect the transformer and parts for moisture and shipping damage. They check the nameplate and print for appropriate voltages and external phasing connections to the bus or line.

Various other tests require proper guidance and the attention of specialists. Control transformers India manufacturers can provide such assistance to their customers during transformer testing.