The transformer oil is an insulating material used in oil-filled transformers and some type of high-voltage switches and capacitors. The functions of a transformer oil are to provide insulation, clamp the Corona Discharge, and to act as a coolant.

Transformer Oil Filtration is a process used to filter out the dirt, dissolved moisture, dissolved gases and sludge particles from the oil which is going to be used in the Oil Transformers.

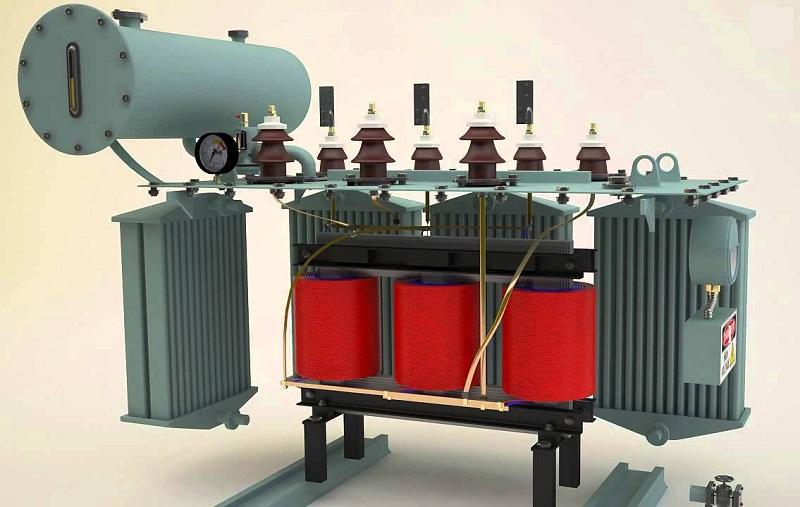

A transformer is an important and powerful component of the Electrical Power Industry which is required to be maintained properly in a certain period of time in order to obtain continuous Power transmission. There are many heavy load transformers that use oil in them. This oil works as an insulating oil and coolant. Alongside, it has many other important functions to perform. Therefore, it is required that oil used should be of good quality and contains no unwanted material in it.

Transformer Oil Filtration Process:

The filtration of transformer oil is done with the help of transformer oil filtration machine and the filtration takes place in a sequence of prescribed steps as shown below.

Step 1- Segregate Moisture and Gas:

The very first step in the process of transformer oil filtration is segregating away the moisture and gas particles from the oil. This segregation is done by raising the oil temperature to a prescribed level. The temperature of the transformer oil is generally raised up to 65° Celsius. This heat segregates the moisture and other gases from oil in the degassing chamber. This heat also helps to reduce the viscosity of the oil which makes the filtration easier.

Step 2- Remove the Sludge:

This step involves the removal of sludge and dirt from the oil in the transformer oil filtration machine. The sludge can be removed from the oil by two different methods listed below:

- By Filter Candles

- By Centrifuging Action

- Sludge Removal by Filter Candles

The Filter candle method of Sludge removal is of two types, first one is the Classical Edge Filter method and the second one is the Depth type filter method. Both of these methods have their own advantages and disadvantages.

1. Sludge removal by Centrifuging Action

The dirt particles and sludge can be removed by the centrifugal process. The reason for using this method is that it is very cost efficient and requires low maintenance.

Step 3- Dehydration & Degasification of the transformer Oil:

The dehydration and degasification of the transformer oil take place in this step. The dehydration is done in the degassing chamber by placing the oil container under required pressure.

The final product that is obtained from the degassing chamber is the good quality oil which now can be used in the transformers. Thus, the filtration of a Transformer Oil is done according to the above process.