The increasing presence of electronics, data and telecommunication products around us means an increasing demand for products like cable glands, particularly brass cable glands. Also known as connectors, the gland attach the cable to the equipment. Consequently, the glands are used in almost all industries with automation and instrumentation – which is almost every industry today!

The cable gland is also an important determinate of an instruments working, since it forms a crucial connecting role. Small and relatively inexpensive, it is nevertheless an important component that must be selected carefully. Here are the factors that you must keep in mind when selecting a cable gland:

Type of Glands:

Before you select one, decide on the types of gland you need. There are different types of glands, including indoor gland, outdoor gland, weatherroof gland, threaded gland, straitening unarmored gland, and industrial type gland. Each of these glands has their own function. For instance, indoor glands are used indoors, while outdoor glands can also be used outdoors. However, in case of more hostile conditions, we need weatherproof glands that are also waterproof. The threaded glands are highly customized, meant for very precise applications. Straitening unarmored glands are used with plastic insulated cables and unarmored elastomeric.

Type of cable:

This is actually connected to the point above because the type of gland will also depend on the type of cable used. This is especially important if you are using armored cable. In such case find out the type and material of the armor, the diameter of the inner bedding and its covering, the armor’s short circuit fault current rating, the cable outer diameter. Unarmored cables, on the other hand, require an outer seal in the gland for ingress protection providing some retention.

Location:

It is important to determine where the cable gland will be attached because this will tell us about the environmental conditions it will be exposed to. Environmental factors like dampness, moisture, high temperature has a direct impact on the integrity of the gland. The location will determine the material and the type of the gland. For instance, weatherproof glands with some kind of elasto meter seal will work best when the location is in comparatively corvine environments. There are even glands that can seal entry against hazardous flammable gases.

Entry point:

You need to decide if you need a threaded gland or entry thread seal. You may also need thread conversion adapter. You should also check the material of the mating enclosure to check that it does not react against the material of the cable gland.

Size:

This is decided according to the diameter of the cable, whether it is the outside or inside diameter that we are considering. Glands are meant to seal connection, which makes the size critically important.

Material:

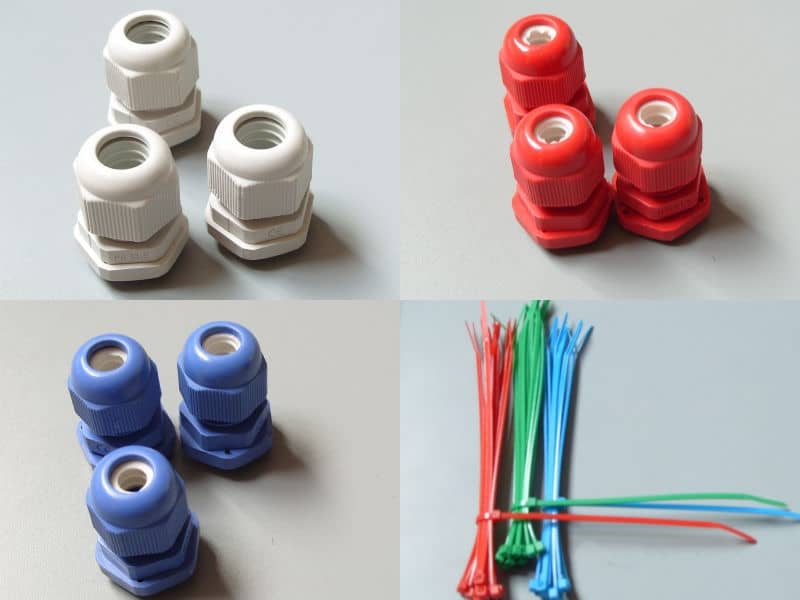

Cable glands are made of a many materials, including PVC, steel, aluminum and brass. Brass cable glands have the advantage of resistance against corrosion. This gives them a much longer life than other materials like steel. For this reason brass glands are used in both indoor and well as outdoor conditions.