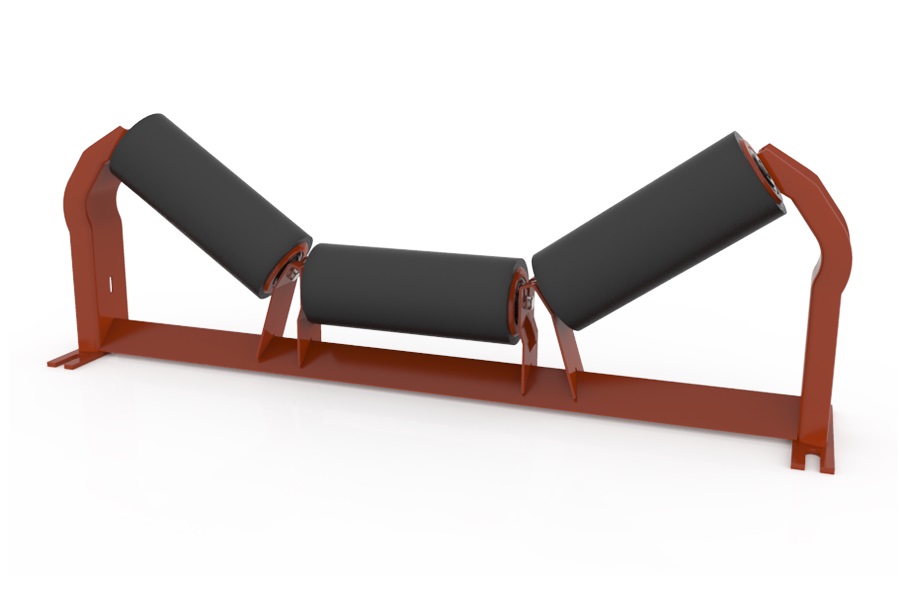

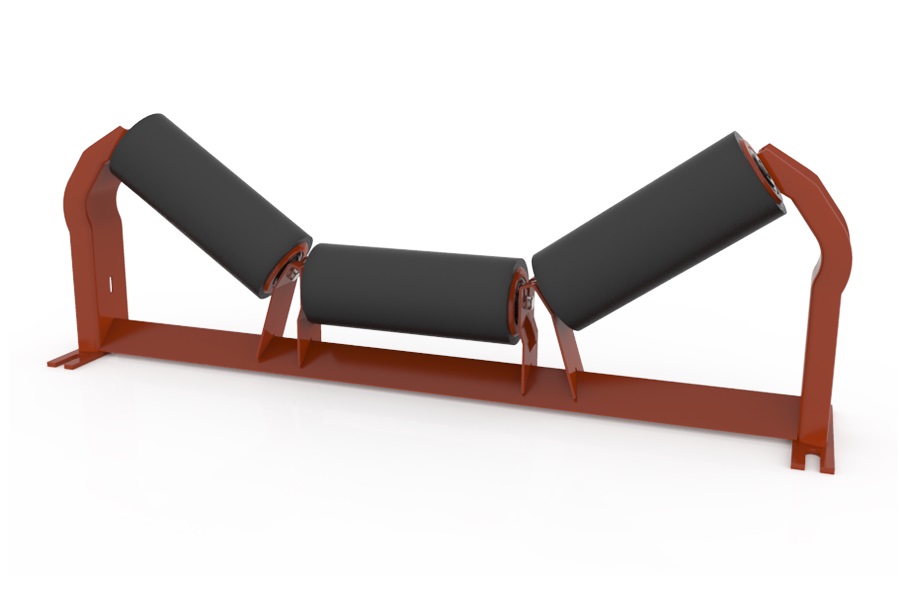

Conveyor roller is a fantastic device that helps in the production process of various products in a manufacturing industry. But it is important to understand, what are conveyor rollers? The conveyors that are impregnated with a set of parallel rotating bars which helps the produced items move from the initiation point till the end is called a conveyor roller. These are mainly used in the manufacturing facilities and warehouses. The conveyor rollers manufacturers produce various types of the products that are used in various industries.

Design

The conveyor rollers are designed in a tailored way that is unique to diversified industries. The size and weight of the product to be manufactured are taken into account before the design is finalized. The manufacturers play a key role in producing the accurate conveyor rollers that help in a huge amount of production without any errors. Engineers have been experimenting to make the rollers more efficient, stronger, and productive. And the necessary changes are done to get the finest product.

Types

The conveyor rollers can be differentiated into two sections. The first category belongs to the rollers that are used to perform heavy duties and the second one is made in such a way that it can manage the light-weighted items proficiently. The proper segregation leads to the production of an accurate product that not only gives the best outcome, but also accomplishes the work within the stipulated budget.

Components

Generally, the conveyor roller consists of beatings, shafts, screw, a large chain, wire mesh, sockets, and belts. Keeping the idea of the components intact, the manufacturers tweak the materials of the components. The alteration is done to support the type of item being produced with the help of the conveyor belt.

The rollers of the conveyor belt are generally made up of galvanized steel, plastic, or PVC. The industry that manufactures enormous but light-weighted items can use PVC and plastic as a component of the screw. Whereas the galvanized steel is one of the strongest metals and can support items with tons of weight. To support the heavy operations, screw conveyors are used, that has a strong machine and highly sustainable belt components.

The conveyor rollers are specific items which are tailored specially to meet the need of the items being manufactured. Hence, duplication of the product is not possible if not specified otherwise. If the conveyor roller malfunctions, specialized personnel are required to fix the same.

Apart from the stereotypical features of the rollers, there are specialized conveyor rollers with features like self-cleaning and low noise. These features make the operation easier for the workers. However, it can be added to the present products if desired by the clients.

The conveyor rollers manufacturers are responsible for making outstanding products that meet the exact need proficiently. The prime motto of the manufacturers is to build a light-weighted item, irrespective of the size of the item it handles. It makes the conveyor rollers user-friendly and easy to maintain. Heavier items are replaced with lighter counterparts that are capable of carrying items which weigh more than a ton.